250tph river stone crushing line in Chile

Material : river stone

Output size : 0-5-10-20mm

Feeding size : max 500mm

Equipment : ZSW1100X4200+PE750X1060+HPT300

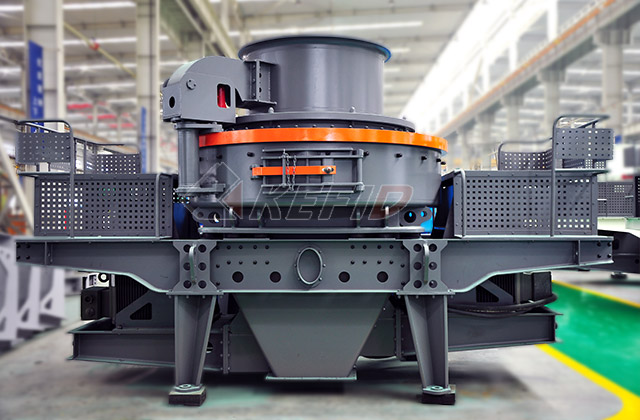

+VSI5X9532+3YZS2160

Application country : Chile

Advantage of the VSI5X sand making machine:

1. Its capacity increases 30% by optimized deep chamber;

2. Operating ratio can be increased 48% by changed side plate direction;

3. The operating cost reduces 30% by combined type worn hammer;

4. Using high temperature resistant and wear resistant material;

5. Bearing is famous international brand that imported from Japan Sweden and America;

6. Perfect graded final products with excellent shape;

7. High exchange rate to utilize any application and material;

8. Spread dish with double purposes can make two feeding ways change easily;

9. Special seal structure under main shaft guarantee no oil leak without seal;

10. It can be used for stationary crushing plant and can be mounted on mobile crushing plant.

Process Description

This clients’ raw materials is high grade river stone, and max 500mm with more than 40% below 150mm. So we specially designed a flow with smaller model jaw+ higher capacity cone crusher+ VSI5X sand making machine and the screens. We use the vibrating feeder to scalp the 0-150mm out and only the 150-600mm goes to the jaw crusher PE750X1060 to crush. These two parts go to the same surge hopper before the hydraulic cone crusher HPT300. There is a small feeder in this surge hopper to feed the HPT300 cone crusher continuously. The HPT300 has a passing ration more than 280tph with CSS=38mm. The 0-40mm sizes will go to the VSI sand making machine to crush and then goes to the vibrating screens. The vibrating screen will separate into the required sizes.