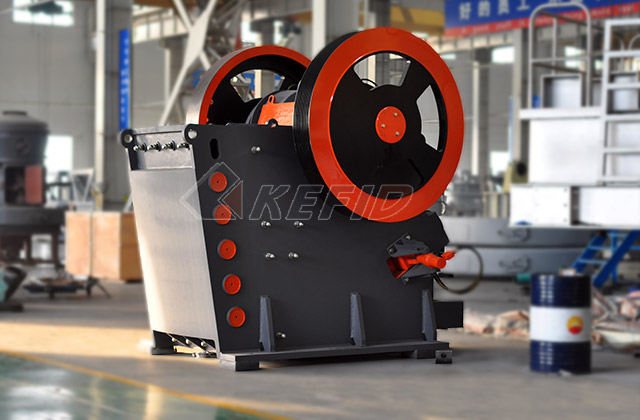

150-200TPH Stone Crusher for Basalt in Ethiopia

Main Equipment : Jaw Crusher + Cone Crusher

Detail: Vibrating Feeder Gzd1100X4200+Jaw Crusher Pe750X1060+Hydraulic Cone Crusher Hpt300C+4Yzs2160

Location : Ethiopia

Raw material : Basalt

Capacity : 150-200TPH

Final size : 10-30mm

Application : Concrete and Highway

One of our customers in Ethiopia his Basalt stones are most below 120mm but little parts are about 300mm. He wants to reduce the size into 30-50mm.

For reducing the invest cost for him we didn't install the big primary jaw crusher because the big size only engages little part mostly is about 50-120mm which can be fed into the cone crusher directly. We install a set of two la

Features Benefits :

1. Increase Production by 20%

2. Safe easy maintenance

3. Easy to change spare parts and wear parts

4. Graded final products with excellent shape

Customer Questions Answers:

1. Q: Can you please send me the complete brochure of your mobile stone crushers to e-mail?

Yes.Please leave a message below with your email.

2. Q: We are setting up a quarry in Harare Zimbabwe. The raw material is granite.Would you kindly recommend the machine?

Yes.Our machines can meet your need. Our engineers and sale manager will design project for you and send you the machines quotation by email.

Kefid will be with you throughout your entire operations. From financing service agreements trainings maintenance. Contact us for the best solution.

Process Description

If you need to make the sands, a set of VSI crusher will be needed after the cone crusher, for making sand and shaping the outputs into cubic shape. Then the outputs are transported to the vibrating screen for screening out the qualified outputs, the bigger ones will be transported back to the cone crusher or VSI crusher for re-crushing.