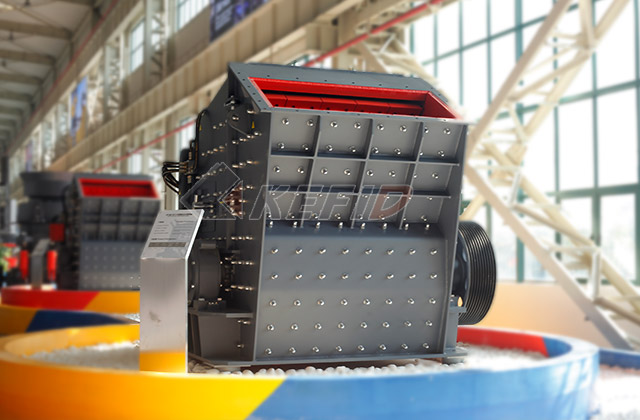

Secondary Impact Crusher

![]() product Capacity:

product Capacity:

Up to 350TPH

![]() Output Size:

Output Size:

Depends on the material

Processed Materials: Limestone, granite, basalt, dolomite, river stone, mountain stone, andesite, quartz, marble, pebble, ballast, Iron ore, gold ore, copper ore, etc.

Applications: Railway, road construcion, other industries.

Introduction of Secondary Impact Crusher

Secondary Impact Crusher is widely used in construction material, highway and railway, cement, mining and chemical fields etc. It is designed to crush soft and medium hard rock. The size range of feed material (maximum compression strength 300Mpa, the moisture should be below 8-10%) can be up to 700mm. Hydraulic impact crusher improves the adjusting device making operation more convenient. The three– cavity makes excellent capability in fine crushing and super fine crushing line.

Advantages of Secondary Impact Crusher

-

1. Hammer is made of high chrome;

1. Hammer is made of high chrome; -

2. Liner board is made of wearable materials;

2. Liner board is made of wearable materials; -

3. Specially designed tooth impact plate;;

3. Specially designed tooth impact plate;; -

4. Excellent cubical final product and high ratio of reduction.

4. Excellent cubical final product and high ratio of reduction.

sales@kefidgroup.com

sales@kefidgroup.com WHATSAPP

WHATSAPP