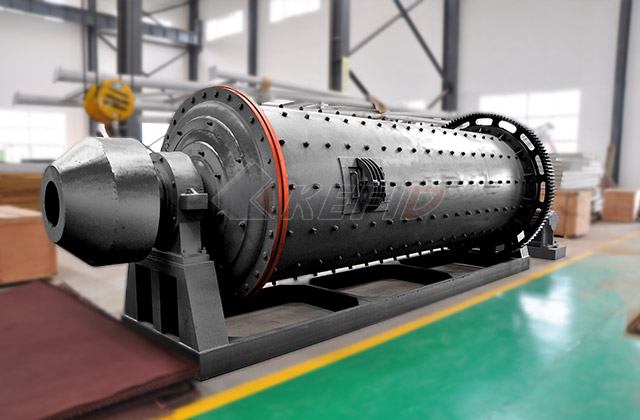

Ball Mill

![]() product Capacity:

product Capacity:

Up to 35TPH, capacity depends on the size of fineness

![]() Output Size:

Output Size:

0.075-0.89 mm

Processed Materials: Limestone, calcium carbonate, dolomite, calcite, barite, talc, gypsum, bentonite, marble, slag, clay, coal, petroleum coke, metal ore, etc.

Applications: cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc

Introduction of Ball Mill

Ball Mill is key equipment which repulverises the material after it is crushed. Our company has been amongst the pioneers for many years in the design and application of milling systems for the size reduction of a wide variety of materials including minerals, ores, and coal. There are two kinds of ball mill, grate type and overfall types due to different ways of discharging material.

Advantages of Ball Mill

-

Advantages of the ball mills are lower investment, energy saving, structure novelty, easy and safe to operate, stable and reliable performance, etc. It is suitable for milling of general and special ore materials.

Advantages of the ball mills are lower investment, energy saving, structure novelty, easy and safe to operate, stable and reliable performance, etc. It is suitable for milling of general and special ore materials.

sales@kefidgroup.com

sales@kefidgroup.com WHATSAPP

WHATSAPP